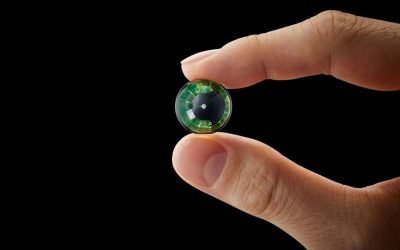

Augmented Reality (AR) is an excellent immersive tool that improves workspace productivity by increasing user interaction. It works by capturing live footage using a camera and superimposing visual 2D / 3D elements on the user’s screen along with the captured real-world elements. With multiple AR apps being successfully deployed on the largest growing smartphone market, this technology has proved to be largely convenient, scalable and mobile; an especially valued aspect in the manufacturing industry. In this context, an AR app that measures the precise distance between two points on all three axes (x, y and z), has multiple use cases, mostly in defect recognition

1. Inspection of Machine Component Assembly

After the assembly of a newly manufactured machine, the inspection of its many compact parts can become a tedious and error-prone task when carried out manually.

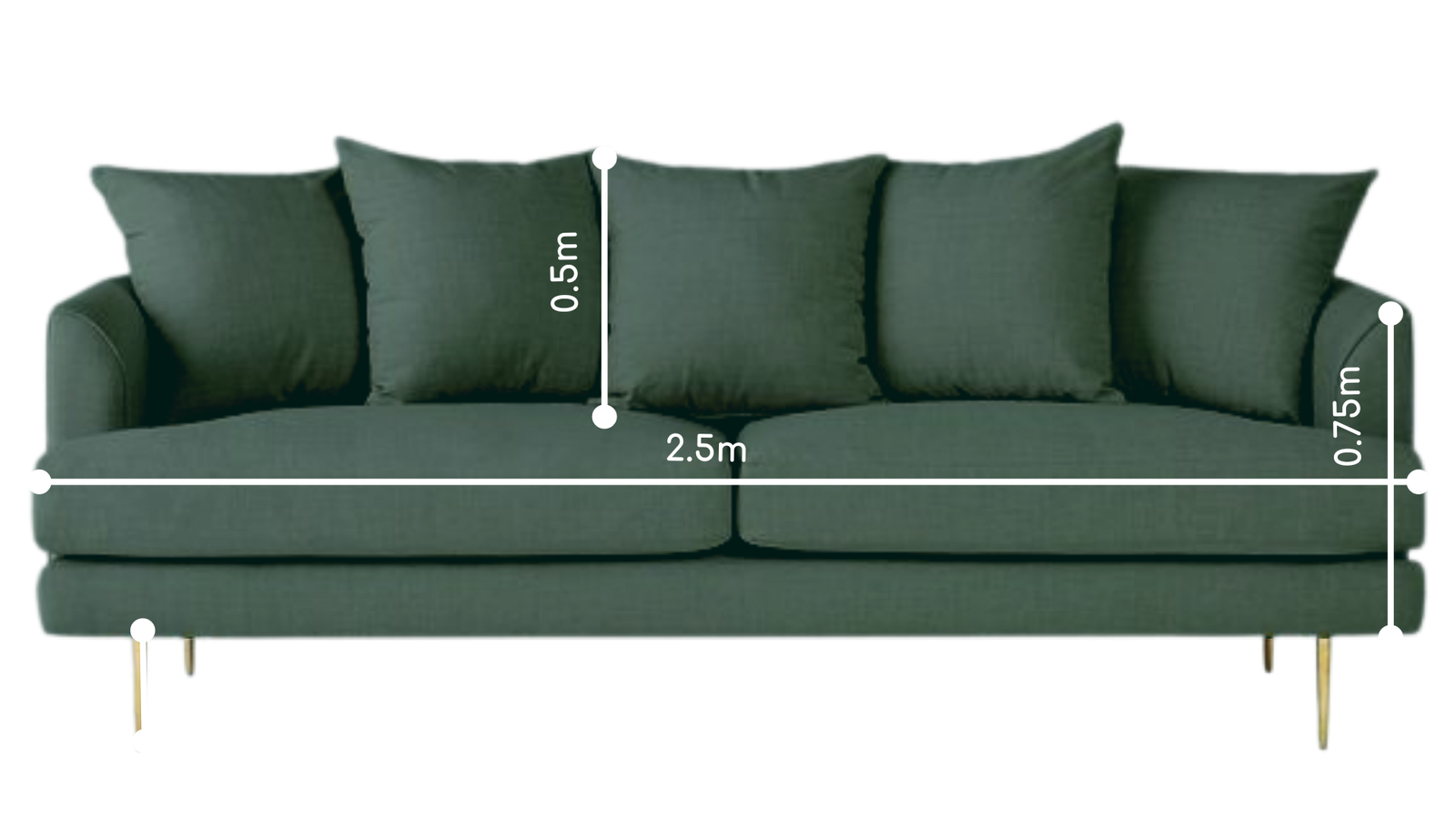

An AR app can automatically indicate whether there is a faulty protrusion of a nut from a bolt, or if the gap between two components of the machine is too large. Not only this, but the app also provides the exact distance measurement of the error.

2. Inspection of Component Wear and Tear

Another use case can be drawn from the detrimental effects of wear and tear on its mechanical components. A measurement tool indicates how much abrasion has occurred due to a pair of metal components in mutual rubbing contact. This is carried out by comparison of the point-to-point measurement of the current width of the components with their original width.

3. Final Quality Check

Measurement parameters can be specified in order to extend application to final quality checks, by classifying products as “accepted” and “rejected”. An AR inspection app can now take user-specified input parameters in order to classify products into these two categories. A decision is made after comparing the measurements with a user-defined threshold, whilst simultaneously providing the exact metrics to be changed if the product is “rejected”.

In conclusion, Measurement using Augmented Reality has proved to be greatly beneficial to the workforce in the industry; workers who earlier relied on their eyes to provide quality end-products to their customers now can effectively use a smartphone application that carries out the process seamlessly. AR makes it possible to even carry out tasks remotely. This helps save time and effort whilst redirecting precious labor and company resources from manual pursuits to intelligent inspection.