Digital solutions provide ubiquitous data, unlimited connectivity, and massive processing power. Fine-tuning these features of digital solutions to cater to the use cases of a company is the core idea of Customized Digital Solutions.

Companies can formulate ideas and improve their operational efficiency by integrating technologies such as Augmented/Virtual Reality, Analytics, Cloud, IoT, AI, blockchain, etc.

As the growth of the digital era expands, the demand for these custom solutions has become a standard in the industry to allow companies to reap greater profits.

What is XR technology?

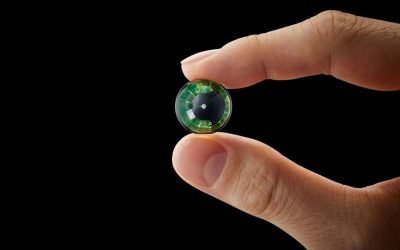

Extended Reality (XR) is an umbrella term encapsulating Augmented Reality (AR), Virtual Reality (VR), Mixed Reality (MR), and everything in between.

The use of XR technology provides an immersive experience for informative content in the form of images, videos, text, etc. to be viewed in a simulated environment or to overlay content on the physical world.

Using these simulations allow developers to automate information, and add interactive features, making the user more immersed in the experience.

Five Examples of Custom XR Solutions:

1) Smart Training

Using an automated training program that allows workers/employees to go through an instruction module composed of content relevant to the needs of the organization reduces training time and effort.

Using Augmented Reality, we can overlay this digital content on a headset which allows the trainee to learn the working of specific equipment in a hands-free manner.

This means that they will be able to view the information in the form of videos, images, and relevant text while using the actual equipment.

2) Augmented Reality for E-commerce:

Augmented Reality can be integrated with e-commerce websites or applications to overlay 3D models of their products onto the physical world.

This allows users who view these products to get a better understanding of the look and feel of the product before purchasing them. The use of these virtual technologies enables users to scale, move, and rotate these 3D models to better fit the environment they are in.

3) 360° Virtual Tours for Real Estate:

An experience can be created consisting of multiple touch points, which when triggered, brings up a 360-degree VR showcase of the living space.

This allows new buyers to experience how their potential home will look when completely furnished. The experience can incorporate elements such as voiceovers, overlaid text, animations, etc., making it an enjoyable and memorable showcase of the living space.

4) Virtual Reality Simulations for Education:

The process of learning in a simulated or artificial environment is frequently referred to as Virtual Reality Training. Over the past fifteen years, VR training has significantly increased due to the development of less expensive and more realistic VR simulators.

Virtual reality training has lately been used in a variety of educational settings, but largely in the domains of technical, engineering, and health and safety education.

The advantage of using a virtual simulation is that it allows students to view and interact with content. An example of this could be displaying relevant text, images, or videos when the student points to a section of an object.

Real-world physics such as gravity, object mass, object collisions, etc., can also be applied to these simulations. This can be used to improve a student’s hand-eye coordination and experience scientific examples in a safe environment.

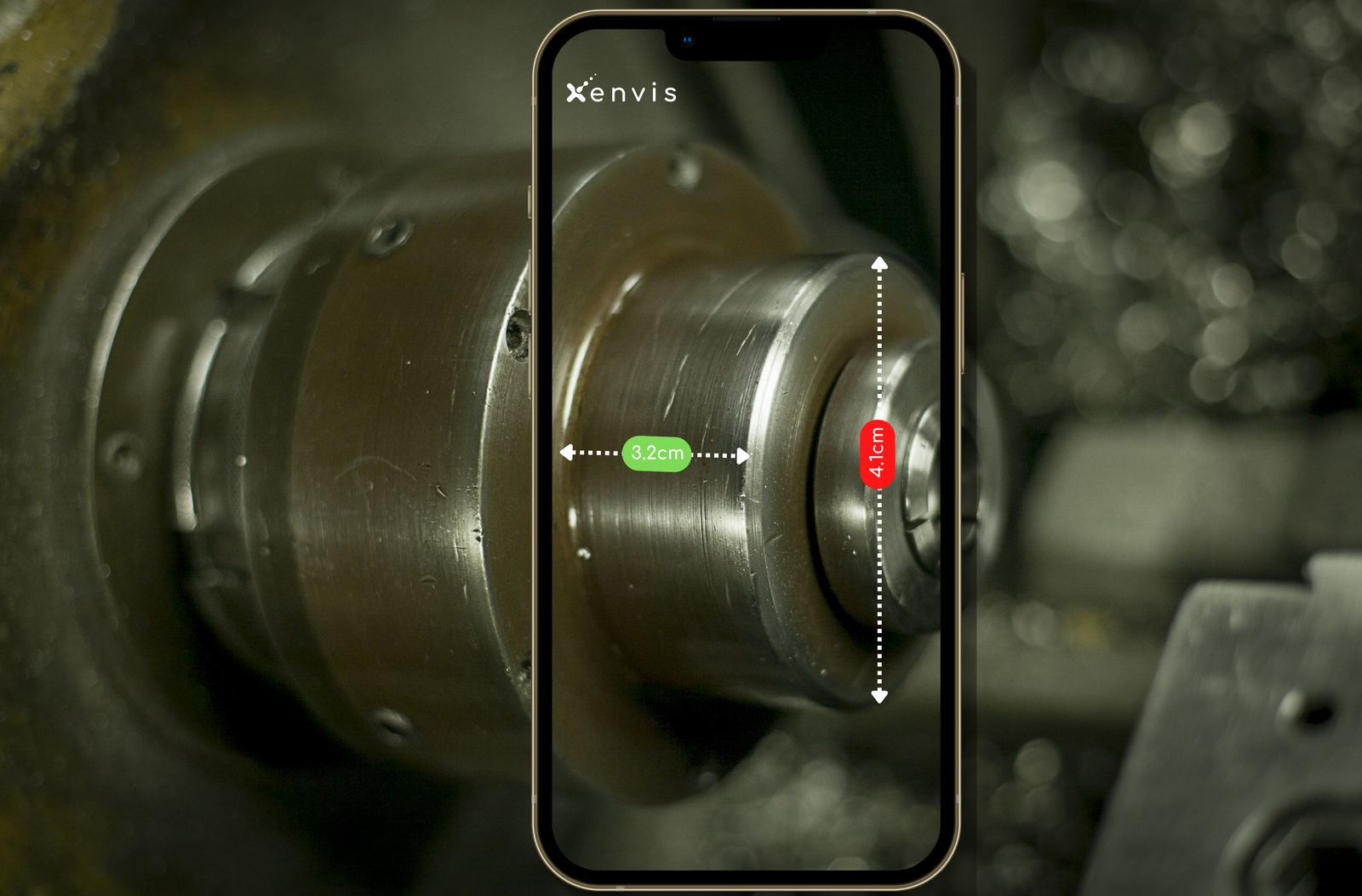

5) Augmented Reality for Maintenance:

Technicians and Engineers utilize AR technology to perform safety checks, optimal measurements, machine assembly, and QATs.

When a technician points the camera to a piece of machinery, wiring, or plumbing, the system shows pertinent information on the screen. Indicators on the screen show which things the SOP (Standard Operating Procedure) documents are referring to. A professional can locate the issue quicker with the help of this technology.

Professionals can also use AR technology to measure linear and angular dimensions, GO/NO-GO detection to detect protrusions in manufactured parts, and detection of variations in machine and process parameters to prevent defects in the final product.

Conclusion:

The benefits of using XR technology are clear, it helps organizations reduce costs for training and servicing, improves the time taken for development, provides a higher retention rate for students/trainees, and creates a more immersive experience for users in general.

The number of companies that are using XR technology is increasing day by day, and how the technology will move forward in the next 5 years will be interesting to keep an eye on.